Integrated

Bindery Systems

Smart-binder Model Comparisons

Benefits of post 2020 Smart-binders, compared to older Smart-binders

Smart-binder enhancements over the years also apply to the Smart Label-binder (SLB)

Since the Smart-binder range was launched in 2004 there have been many enhancements made to improve the machine performance, and ease of use. Many new optional features and new machine configurations are also now available.

Smart-binder with trimmer waste conveyor, cover feeder and autoloader

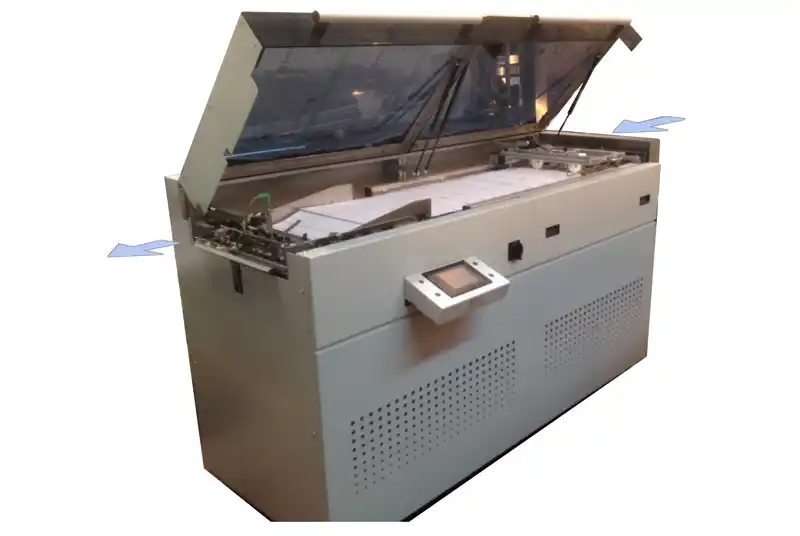

The Smart-binder now has new Improved 'curved' machine guards with detachable windows

Smart-binder with guards raised

Enhanced Performance and Ease of Use

Increased sheet input speed

Sheet input rate increased to 8 sheets/sec. Can now connect to a web cutter at web speeds up to 130m/min (426 ft/min), or 180 m/min (590 ft/min) with additional in-line buckle-folder F-100.

Variable infeed and folder speed

The infeed conveyor and folder velocity can now be easily adjusted from the Smart-binder touch screen. Allows infeed velocity to be varied, to help run very light weight sheets.

Increased booklet output speed

The stitcher and trimmer cycle speed has been increased to 7000 cycles/hr giving a 27% increase in output speed when producing thin booklets (e.g. 8pp & 12pp). This has been made possible through the introduction of a new indexing (high speed) book transport system through the trimmer.

Increased maximum book thickness to assist maximum 10mm thick booklet production

Changes have been made to the trimmer to increase cutting

force and increase knife life when making thick booklets.

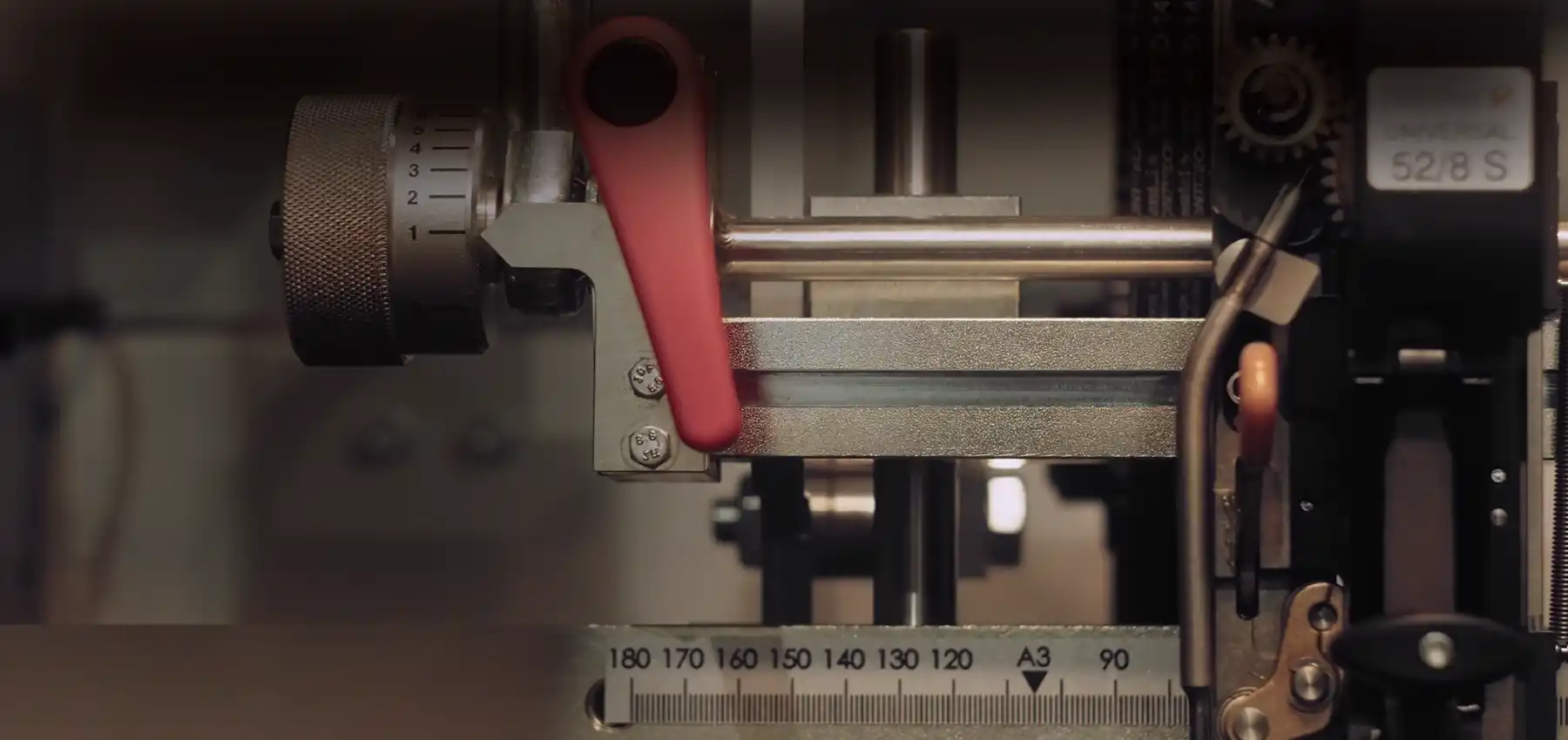

Wire stitch heads have been uprated for stitching of 10mm thick booklets

(new 52/8S heads used).

Cover feeder enhancements

A Cover ‘Autoloader’ (with optional cover code reader to provide 'cover matching') has been added to increase max cover pile height from 20mm to 200mm and to ensure more reliable cover feeding:

2D code reading

New code readers are now offered for a wide range of 2D (and 1D) codes.

Electrical drive, system controls and software

The Smart-binder drive and control system has been upgraded to use

modern up-to-date and readily available components.

Note: It is increasingly difficult to source some replacement electrical

components used on old version Smart-binders.

New Windows 10 Operating system and C# software (.NET) introduced summer 2020 to replace old operating system and software.

Other performance enhancements

Hardware and software improvements have been made to all areas of the machine to improve performance, increase book quality and make the machine easier to use and maintain.

Code-driven automation

It is now possible to add digits to the code printed on each sheet to automatically control the following:

- Selective gluing

- Selective cover feeding

- Selective perforation

- Cover matching

- Insert feeding and matching

- Corner cutting

Direct control of the web cutter

The upstream web cutter (model Tecnau TC7000) can now be controlled directly from the Smart-binder. This enables the cutter to feed sheets for each booklet at the optimum rate to keep the Smart-binder running at a high output speed when producing booklets with constantly varying pagination.

Missing Stitch Detection

All Smart-binders now include a missing wire-stitch detection system which will stop the machine if a wire staple is missing.

Additional Features, Options and Modules for Special Applications

1/ Modules for installation prior to Smart-binder infeed:

F-100 buckle folder

By installing this folder inbetween the web cutter

and the SB infeed the maximum web speed can be increased from 130

m/min to 180 m/min. This folder may also be used to help run very

lightweight paper stocks at high speed.

Each sheet is cut to double the normal length (so it contains 8 pages

instead of 4 pages) and is then buckle folded in half before it enter

the SB.

delivery into

Smart-binder

F-100 cross-folder

F-200 buckle folder

This does the same job as the F-100 folder (above) but has dynamic fold capability. This means 8-page sheets and 12-page sheets can be mixed together. The 8 page sheets are folded once and the 12 page sheets are folded twice (2 fold plates selected instead of one). In this way the number of pages in the booklet can be varied in normal 4-page increments instead of 8-pages.

RF-100 rotator and buckle folder

This folder allows smaller format booklets (eg: 5 ½

x 8 ½ ) to be produced from a normal 18” wide web and

avoids the need to reduce the web width to (say) 12-13” which

is inefficient for the printing process (unless two 12” wide

rolls can be created from a 24” wide web).

The sheets are cut to contain 8 pages. The RF-100 rotates each sheet

by 90 degrees and then buckle folds it in half before it enters the

SB. The RF-100 can operate at web unwind speeds up to about 91 m/min

(300 ft/min).

Sheet rotation options, SR-100, SRM-100

Different types of sheet rotator are available for installation prior to the Smart-binder infeed (in-line applications).

New ‘TUSDC’ method to produce small format booklets from a wide web

The TUSDC-100 modules may be installed inbetween a web cutter and the IBIS Smart-binder to enable A5 (or 5½ x 8½") booklets to be produced from a 450mm (or 17½ - 18") wide web using 4-page sheets.

to change

sheet

direction

conveyor

TUSDC Modules

Sheet buffer module SBS-100

The sheet buffer module may be used when running in-line to allow the web printer to continuing running at a constant feed while varying the rate of feed into the Smart-binder to suit the pagination of the booklet being produced. Allows booklets to be produced with constantly varying pagination when running in-line. Also enables the Smart-binder to stop for a short time without stopping the upstream printer.

delivery into

Smart-binder

from web-cutter

Sheet Buffer SBS-100

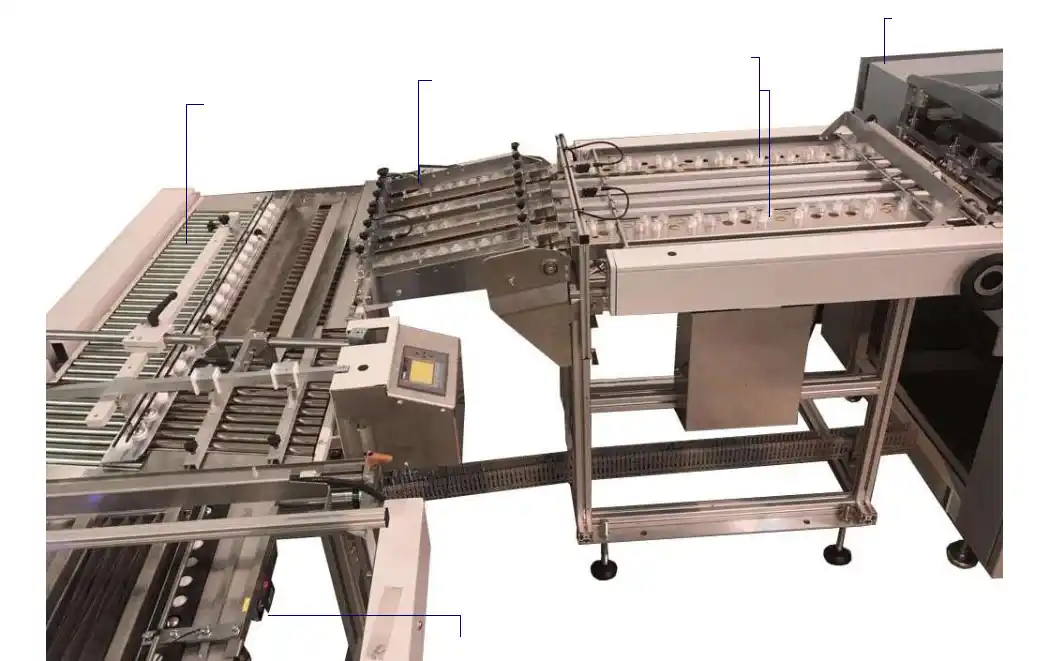

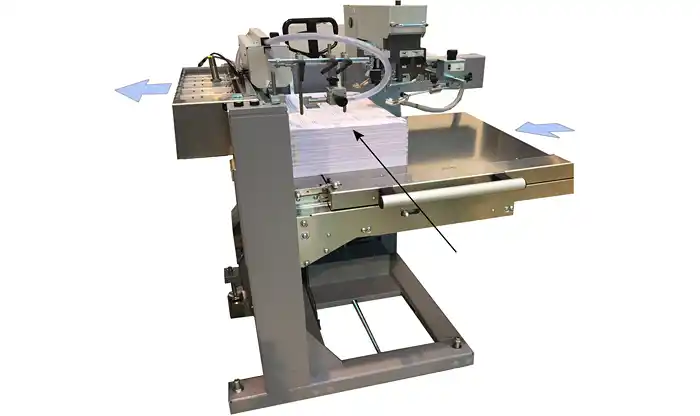

Different types of sheet pile feeder SB-095, -096 or -097

In addition to the standard high pile feeder SB-095 we now offer a new feeder SB-097 which includes a sheet bridge conveyor. This allows the feeder to be installed in between the web cutter and the Smart-binder. With the SB-097 fitted, then sheets can either be fed into the SB from the web cutter (via the feeder bridge conveyor) or fed from a pile of sheets loaded into the feeder.

feed into

Smart-binder

sheet entry

from web-cutter

Sheet Pile Feeder SB-097

A section of rollers (option RRT-106) may be added to the SB-097 lift table to receive sheet piles from the upstream sheet stacker (replacing the need for the Hunkeler TS-6 module).

The optional SB-096 feeder can be located on the side and includes a sheet direction changer. This allows sheets to be inserted into the sheet stream coming from another in-lone sheet feeder or from a web cutter.

Loading trolleys available for sheet feeders (PLT-100 and HPL-100)

The PLT-100 and HPL-100 loading trolley systems are now available for the SB-095 (or SB-096) sheet feeders. The HPL-100 trolley is also available for the SB-097 sheet feeder. These reduce the time taken to reload piles from a few minutes to about 35 secs.

2/ Options Available for Installation in the Smart-binder:

Dynamic sheet micro-perforation DMP-100 or DMP-101

The sheet perforator module may be installed in between the Smart-binder infeed and the sheet scoring module. This provides up to four longitudinal lines of micro-perf to allow, for example, selective sheet tear-out. An extra digit in the bar code dynamically controls the actuation of the perf on each sheet.

Sheet Perforator Module DMP-100

Single knife trimmer (reduced price option)

The Smart-binder may now be supplied with a lower-cost trimmer containing only a face knife, instead of the normal 3 trim knives (face, head and foot)

Lower speed, lower cost Smart-binder model SB-1

A lower speed, lower cost variant of the Smart-binder is now available to run in-line with cut sheet printers

Trimmer center knife CKN-100, 101 or 102

Three different center-knives are available : a double bladed knife with ¼” or 3/8” center trim out, and a single bladed knife (no trim out). The single bladed knife offers the benefit of being able to center-cut very thick booklets whereas use of the double bladed knife is restricted to about 5mm booklet thickness

Trimmer corner-hole punch CHP-100

An optional punch system may be fitted in the trimmer to punch a hole in the corner of the booklet spine when it stops for face edge trim

Hole-punching systems: separate modules

A variety of separate hole-punching or hole-drilling modules are available to connect to the Smart-binder delivery. Typically these are used to punch or drill multiple ‘file’ holes in the booklet spine

Additional cover feeder or insert sheet feeder CIF-101

It is now possible to provide a Smart-binder with two cover or insert sheet feeders, one after the other

Additional sheet feeder on the side SB-096

If booklets need to be made from two different piles of sheets then we now offer an addition sheet pile feeder on the side. This will merge sheets fed from pile feeder #2 with sheets fed from feeder#1 in any combination. One Smart-binder customer is currently using this to make booklets containing some separately fed NCR sheets.

Stitcher automatic inhibit system SDI-100

Automatically inhibits the wire stapling under bar code control, or when running out booklets at the end of the job. Allows on-the-run switching between wire stitching and ISG cold glue binding

100Kg wire spools

100Kg floor mounted wire spools are now available with wire feed system, instead of 2.5K spools mounted on the machine. A spool lifting trolley may also be supplied to assist reloading the spools.

Optional ‘higher level’ trimmer waste removal system TWC-100 or TWC-101

If a vacuum waste extract system is not available then two types of waste removal conveyor are available to deliver trimmer waste into a bin next to the Smart-binder : either low level (standard) for high level (special option) . The new high level systemTWC-101 allows use of a standard factory large capacity ‘wheelie bin’ to collect the waste

Trimmer side clamp kit to reduce spine corner tearing TCA-100

A trimmer side clamp kit may be fitted to clamp the book spine in a way that reduces or eliminate the spine corner tearing which occurs when side trimming very thick saddle-bound booklets

Smart-Data Analysis system SDA-100

The new Smart-data Analysis package presents detailed production data and fault logging on a separate screen

3/ Modules available to connect to the Smart-binder delivery

Post trimmer knife folder MS-45

A knife folder may be connected to the Smart-binder delivery to fold each finished booklet in half.

Booklet or signature stackers BSS-10, BSS-20 or BSS-30

A range of different booklet stackers may be connected to the Smart-binder delivery. An optional code detector can be fitted to allow ‘intelligent’ stacking : for example ‘classroom stacks’ (for exam papers) or signature stacks (for perfect binding).

Strapping module PS-100

A strapping module may be connected to the output from the booklet stacker to automatically apply a strap around the booklet pile.

In-line perfect binding PB-1500W (SB-4 system)

The 5-clamp perfect binder PB-1500W is available to operate in-line with the Smart-binder delivery. In this case the Smart-binder delivers signatures (which may be ISG cold glue bound inside) that are collected on top of each other and delivered automatically into the perfect binder. Perfect bound book production up to 70mm thick with no manual handling required.

In-line spine squaring module SM-101

A spine squaring module SM-101 may be connected to the Smart-binder delivery to press each booklet spine into a square shape.

In-line booklet edge sealing

An edge sealing system may be provided for document security. The cover sheet is wide than the inside sheets allowing it to be automatically opened, glued and then closed. The booklet can then only be read by tearing open the edge seal. Perforations may allow the sealed edge to be more easily opened.

90 degree bend delivery conveyor

A 90 degree book delivery conveyor may be fitted to reduce the overall Smart-binder system width, if needed.

In-line insertion for mailing applications

Recent Smart-binder installations include an in-line inserter to add insert sheets or tip-on cards to the booklet and place the booklet + inserts (or tip-ons) into an envelope for direct mailing.

4/ Special Modifications to Expand Max/Min Booklet Format Size

SB-X ‘stretched’ Smart-binder for booklet format sizes larger than the normal maximum

The alternative model ‘SB-X’ has been extended in the saddle direction to be able to produce booklet spines up to 18” in length. This can either be used to produce very long booklets or 5 ½ x 8 ½ booklets in 2-up mode (using the trimmer center knife) at speeds up to 11,000 booklets/hour.

SB-W modifications to increase max sheet width and booklet width

The SB-W modification increases the maximum sheet width from 470 to 546mm and also increases the maximum trimmed booklet width from 230 to 267mm.

5/Special modifications to reduce the normal minimum booklet format size

With special modifications we are now able to reduce the SB minimum sheet width from 250mm to 175mm and the minimum trimmed booklet width from 119mm to 82.5mm.

6/ Latest Smart-binders - System Configurations and options